Take a More Strategic Business Outcome Focused Approach to PPM

From the need to embrace disruptive technologies to dealing with ongoing stubborn supply chain challenges, manufacturers find themselves operating in trying times. The continued ability to optimize new product development, streamline operations and delight customers while maintaining profitability depends on doing the right things in the right way, every time.

Be More Than Just a Status Quo PMO

Avoiding Disruptive Technology Disruption

Regardless of the manufacturing sector you operate in, you can’t avoid the impact of disruptive technologies. From the features and functions of your products to the way those products are produced and delivered, to the way you run your internal operations; technology is changing everything. Success comes from being able to leverage those technologies to your advantage. To turn potential disruption into opportunities, resulting in innovation, efficiency and ultimately higher performance.

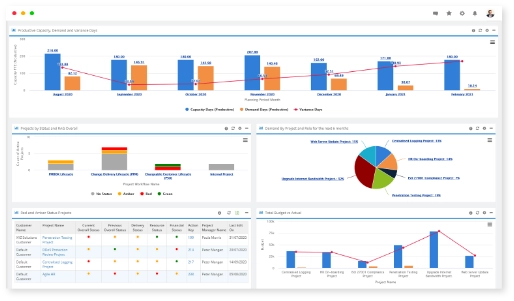

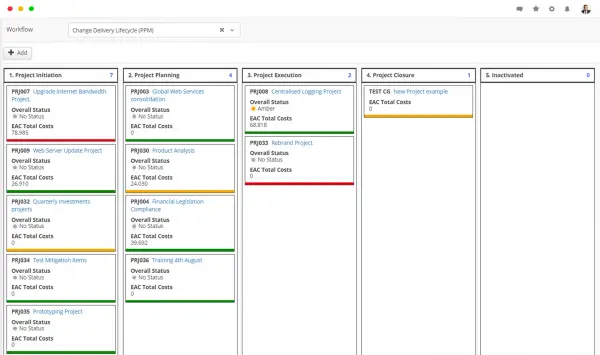

Achieving that requires a strategic approach to digitally transforming your business. You need to align your strategic priorities, your investments, and the work you commit to with the benefits that you expect to achieve. That requires an effective PPM solution that allows you to manage everything from the top, to adjust quickly and easily when actual results vary from expectations, and to evolve to embrace emerging technologies as they happen.

Optimized New Product Development

In today’s world, new product development isn’t just about getting products to market. Sure, you need to be able to minimize the timeline from ideation to commercialization, but you also need all of your projects to work together to form a strategic market coverage approach. You need effective lifecycle management to ensure that products never remain in market beyond their optimal profitability, and that there are always replacements waiting to take their place.

This requires a complex mix of variables from suppliers and R&D to production and customer service. Managing that requires an overall strategic roadmap, visualized and realized through a world class PPM solution like that offered by KeyedIn. That ensures all stakeholders have a shared vision, and allows leadership to manage performance against metrics that matter – value metrics that directly relate to overall corporate performance.

New Challenges, New Solutions

The manufacturing sector today is facing new challenges that require new solutions and approaches. ESG (environmental, social and governance) is becoming an increasingly important business driver, requiring environmental awareness and sustainability in product design, production, delivery and disposal. It requires some manufacturers to reconsider the social implications of their products and positioning, and for all manufacturers it is driving a need for closer, more collaborative, relationships with customers.

At the same time, ongoing supply chain challenges are forcing manufacturers to rethink how they operate, from bringing supply chain elements in house to sourcing new materials and / or suppliers, to fundamentally reimagining the production and delivery process. All of these challenges promise to fundamentally redefine what it means to be a manufacturer, and they need to be absorbed without impacting the ability to continue delivering products to market efficiently, effectively, and profitably.

The many strategic investments required to achieve that need to be managed through a comprehensive PPM platform that can align all strategic priorities and manage the full portfolio of investments. Decisions must be made with a full understanding of the impact on both current and future needs; options must be analyzed with a full understanding of the impacts on dependent initiatives, and decisions must be capable of being validated through powerful reporting tools.

Optimized Operations – Every Day

Modern manufacturers operate lean. Operational processes are automated wherever possible, streamlining workflows, automating appropriate approvals, and minimizing the time spent flowing through the system. Whether it’s the manufacturing plant itself or the various support processes from financials to procurement; resources to technology; every step of a manufacturing business has to be as efficient as possible.

The problem is that yesterdays optimized is tomorrow’s obsolete. Technological advancements, competitive innovations and evolving customer demands require a continuous reimagining of what excellence looks like. Delivering that excellence on an ongoing basis means investing appropriately in all areas of a company’s operations, and managing those initiatives centrally to ensure that value is being improved and optimized with every piece of work. The only way to manage that many moving parts is with an effective PPM solution.

Easy and Fast Implementation with easy education for the end users

"Quick, efficient! From the top of the application implementation it was easy to educate the end users. The application is easy to navigate and has excelled reports to keep everyone on track. Overall I would recommend this application to others."

Clinical Implementation Specialist in the Healthcare Industry

A selection of our customers in the Manufacturing industry.

- Solenis

- Bodycote

- FujiFilm

- Emerson

- NCH Corporation

- Ossur

- Trivium

- Graymont

- Belron

- Vion Food Group

- Johnson Matthey

- Ardagh Group

- Kone

- Burckhardt Compression

- Danagher

A Year in the Life of KeyedIn

Learn from Vitality Health as they describe their partnership with KeyedIn.

Download the Case StudyInsight Sourcing Group

Learn from the Insight Sourcing Group as they describe their journey to improved resource management.

Download the Case StudyMEDHOST

Learn how improved resource management helps MEDHOST® cope with rapidly fluctuating client demands.

Download the Case StudySolenis Case Study

How Solenis Created an Enterprise PMO for Data-driven Analysis and Corporate Success

Download the Case Study Case Studies

Solenis Case Study

How Solenis Created an Enterprise PMO for Data-driven Analysis and Corporate Success

Download the Case Study Case Studies

A Year in the Life of KeyedIn

Learn from Vitality Health as they describe their partnership with KeyedIn.

Download the Case Study Case Studies

Insight Sourcing Group

Learn from the Insight Sourcing Group as they describe their journey to improved resource management.

Download the Case Study